Custom P&ID Project Configuration: Tailored Solutions for Your Company

- Edi Nuhanovic

- Sep 3, 2024

- 3 min read

Creating Piping and Instrumentation Diagrams (P&IDs) is a crucial part of the planning and documentation of technical facilities. Each company has specific requirements and standards that must be considered in P&ID projects. A customized P&ID project configuration ensures that the diagrams not only comply with international standards, but are also optimally adapted to the company's internal processes and guidelines. In this blog post, we will highlight the key aspects of a tailored P&ID project configuration.

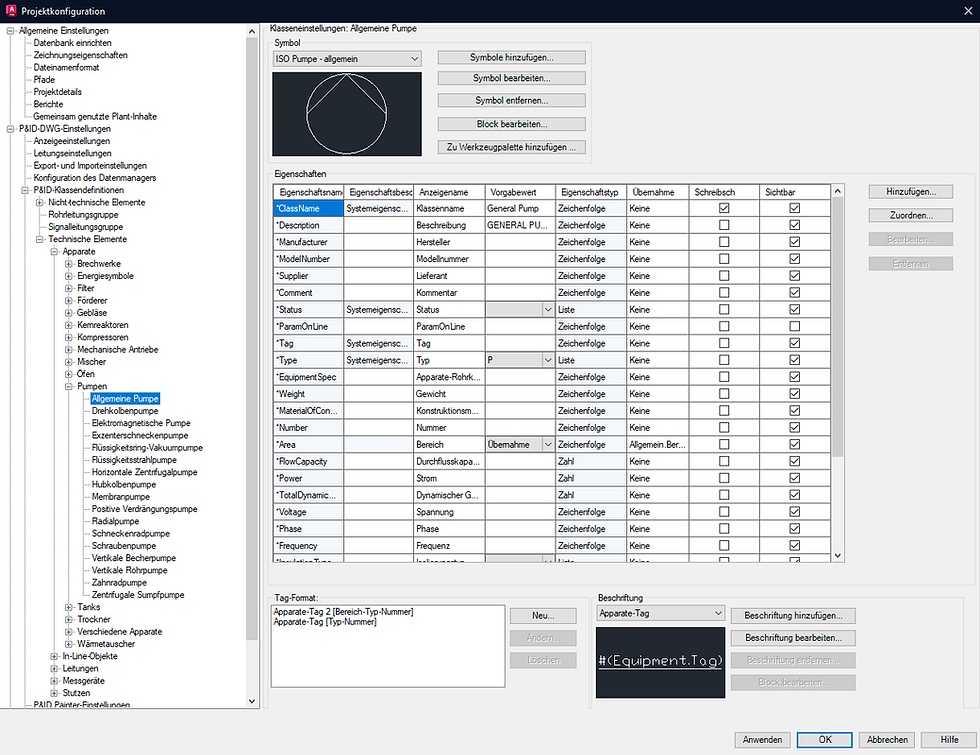

1. Custom Symbols: Tailored Representations for Your Project

In many industries, standardized symbols in P&IDs are widely used to ensure the readability and understanding of diagrams. However, specific requirements or unique facility components may necessitate the use of custom symbols.

The development and implementation of custom symbols offer the following advantages:

Specific Requirements: Unique facility components or special control systems can be represented more accurately with tailored symbols.

Clarity and Consistency: The use of custom symbols ensures that all stakeholders interpret the representations uniformly.

Corporate Identity: Utilizing company-specific symbols strengthens corporate identity and differentiates technical documentation from that of other companies.

2. Company-Specific Tagging System: Structured Identification for Your Projects

A company-specific tagging system is essential for organizing and managing components within technical facilities. A customized P&ID project configuration allows for the implementation of such a tagging system to meet your specific needs.

The advantages of a tailored tagging system include:

Standardization: All components are identified according to a uniform scheme, which enhances clarity and traceability.

Efficiency Gains: A standardized tagging system can reduce errors and increase efficiency in the maintenance and operation of the facility.

Easy Integration: P&ID software can be configured to automatically incorporate your company's tagging system into the diagrams, minimizing the need for manual adjustments.

3. List Configuration for Excel and PDF: Optimized Output Formats for Your Documentation

Creating and managing lists is an essential part of any P&ID project. These lists typically include component lists, instrument lists, piping lists, and more. A customized list configuration allows these details to be efficiently exported in the required formats (e.g., Excel, PDF).

Key benefits of custom list configuration include:

Flexibility: You can specify which information appears in the lists and how it is structured to meet your company's needs.

Automation: Automatically generating lists in the desired formats saves time and reduces potential errors.

Export Options: With the ability to export lists in both Excel and PDF formats, data processing and distribution are simplified.

4. P&ID to P3D Configuration: Seamless Integration into 3D Planning

Integrating 2D P&ID diagrams into three-dimensional (P3D) planning is a vital step in project development. An optimal P&ID project configuration enables a seamless connection between 2D and 3D data.

Advantages of P&ID to P3D configuration include:

Data Consistency: Direct transfer of P&ID data into the 3D model ensures consistency between planning phases.

Efficient Planning: Changes made in the P&ID can be automatically transferred to the 3D model, significantly speeding up the planning process.

Error Minimization: Linking P&ID and P3D reduces the risk of errors that could occur during manual data transfers.

Conclusion

A customized P&ID project configuration offers significant benefits for companies with specific requirements in facility planning. Through tailored symbols, a company-specific tagging system, optimized list formats, and the integration of P&ID into 3D planning, efficiency, consistency, and clarity in projects can be significantly improved. By customizing your P&ID software accordingly, you ensure that your projects not only meet international standards, but are also perfectly tailored to your operational needs.

Link to service:

Comments