Optimizing Plant 3D Project Configurations: A Comprehensive Guide

- Edi Nuhanovic

- Sep 3, 2024

- 2 min read

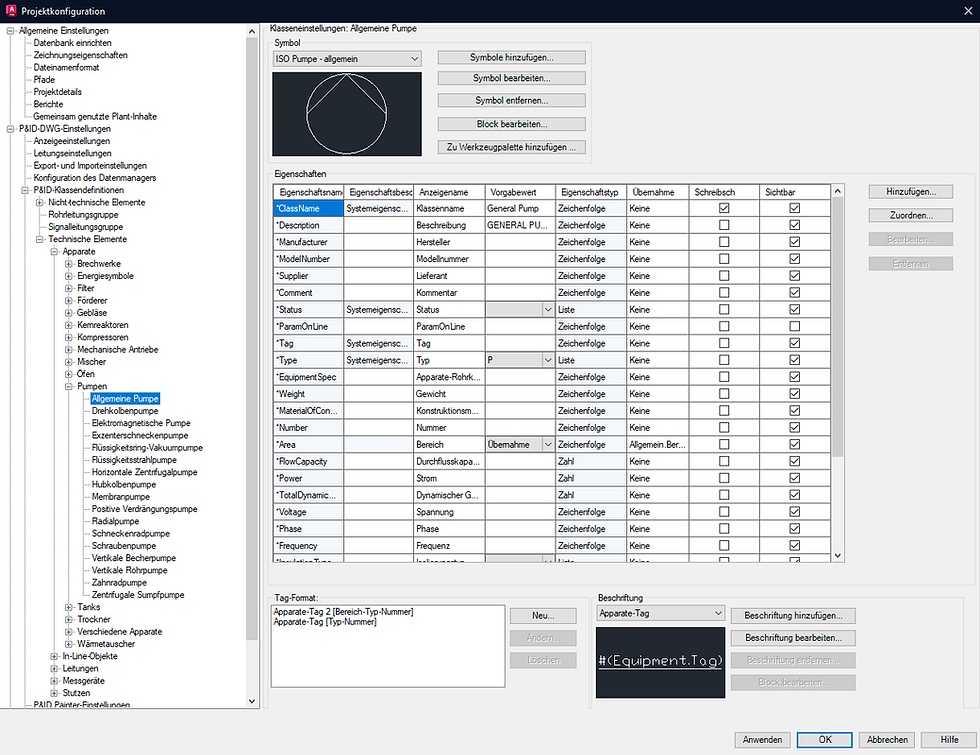

Autodesk Plant 3D is a powerful tool for designing, modeling, and managing piping and instrumentation diagrams (P&IDs) as well as 3D plant layouts. However, to fully leverage its capabilities and meet specific project requirements, it is crucial to customize and configure Plant 3D to align with your company’s standards and workflows. In this blog post, we will explore the key aspects of Plant 3D project configurations that can help you optimize your workflow, improve data consistency, and ensure project success.

1. Setting Up Project Standards: Consistency and Quality Assurance

The first step in configuring a Plant 3D project is establishing company-specific standards. These standards include norms for piping and instrumentation diagrams, drawing templates, fonts, layer structures, and more.

Benefits:

Uniform Representation: Established standards ensure that all project participants work according to the same guidelines, increasing the consistency of project documentation.

Quality Assurance: Predefined standards help detect and avoid errors and deviations early in the process.

Efficient Workflows: A uniform structure facilitates collaboration between different teams and departments.

2. Custom Pipe Specs and Catalogs: Tailored Components for Your Needs

Customizing pipe specs and catalogs in Plant 3D is another crucial step in optimizing project configuration. This allows the use of company-specific or project-specific pipe specs, materials, and components.

Benefits:

Project-Specific Adjustments: You can tailor pipe specs and materials to exactly meet the requirements of your project.

Time Savings: Using predefined and verified components can accelerate planning processes and reduce errors.

Cost Control: Selecting the right materials and components can help keep project costs within budget.

3. Report Generation and Output: Optimized Documentation for Stakeholders

A key part of any Plant 3D project is generating reports and outputs that document project progress and are available to all stakeholders. Configuring the report generation process allows you to create customized reports that meet the exact needs of your project.

Benefits:

Customized Reports: You can create reports tailored to the needs of different project stakeholders, whether for management, the engineering team, or the client.

Automation: Once configured, reports can be generated and exported automatically, significantly reducing the documentation workload.

Various Output Formats: Reports can be output in various formats, such as PDF, Excel, or XML, to meet the needs of different audiences.

4. P&ID Integration into 3D Models: Seamless Connection Between 2D and 3D

One of the greatest strengths of Plant 3D is its ability to integrate P&ID diagrams directly into 3D models. Carefully configuring this integration ensures that changes and updates in the 2D P&IDs are automatically reflected in the 3D models.

Benefits:

Consistency Between 2D and 3D: The integration ensures that all changes in the P&ID diagrams are directly reflected in the 3D model.

More Efficient Planning: Planners can work directly in 3D while maintaining the precision and detail of the P&IDs.

Error Minimization: Automatic incorporation of changes reduces potential errors that could arise from manual transfers.

Conclusion

Configuring Plant 3D projects offers numerous opportunities to optimize your plant design process. By setting up project standards, customizing pipe specs, managing report generation, and integrating P&ID diagrams into 3D models, you can ensure that your projects are carried out efficiently, consistently, and successfully. By tailoring Plant 3D to your company’s specific requirements, you maximize both productivity and the quality of your project outcomes.

Link to service:

Comments